.

COMPOSITE HOSE ASSEMBLIES

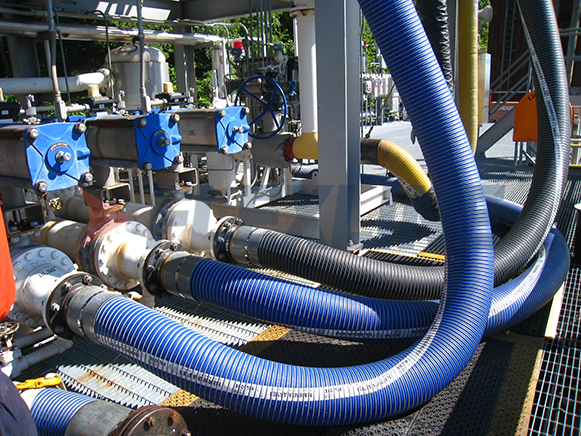

Composite hose assemblies are used in any application that benefits from a flexible, safe and chemically resistant hose.

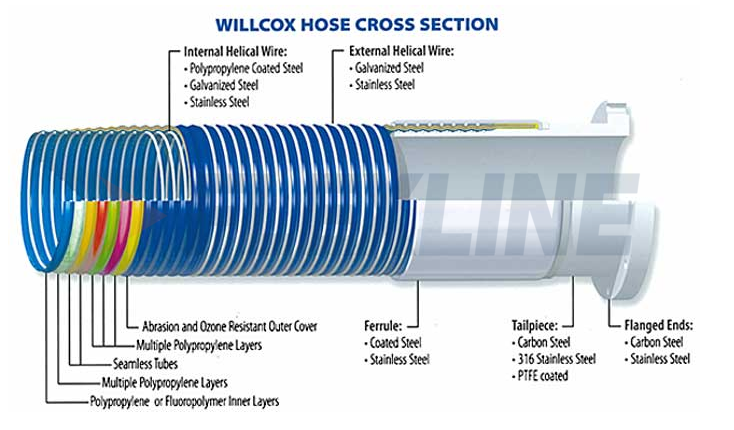

Flexible: Composite assemblies are more flexible than almost any other hose types. When composite hose is moved or bent, the layers slide over each other, making the hose very flexible and providing for small bend radii.

Safe: Composite hoses provide some “fail safe“ characteristics. The construction consists of layers of tubes and film. For a leak to occur, liquid must serpentine its way through the many layers until it reaches the outer cover. Once the liquid reaches the outer cover, small drops will form along the seam line indicating that a leak is occurring. The end fittings are specifically designed to reduce the chance of a fitting blowing off the end of the hose. The fitting’s spiral shank screws into the composite hose before swaging, creating a more secure end fitting connection.

Chemical Resistance: Composite hoses are most commonly used in the transfer of chemicals. The bore of the hose can be made from polypropylene, Teflon and Nylon, compatible with most common chemicals.

Composite Hose

Flexline manufactures the complete line of Willcox Composite Hose Assemblies in sizes 1” through 14”. We offer multiple products to best meet our customer’s requirements. Our offerings include:

Chemical Transfer Hoses: 3081 PG, 3091 PG, 3094 PS, 4091 SG.

Petroleum Transfer Hoses: 1061, 1091, Bottom Loading Hose, and Vapor Recovery Hose.

Large Diameter Marine Dock Hoses: 1151, 3161, 4161, and Marinemaster.®

Ethanol, Biodiesel, and Cryogenic Composite Assemblies for LPG and LNG applications in sizes 1” to 10” diameters.