.

SILICONE HOSE

High Purity Silicone Hose Assemblies and Tubing

Flexline’s platinum cured silicone hose assemblies are flexible and can be sterilized with SIP, CIP, autoclave, and irradiation with gamma radiation. They are lot traceable. Our silicone hoses are USP Class VI certified and also certified to: European Pharmacopeia 3.1.9, FDA 21 CRD 177.2600, 3-A Sanitary Standards and ADI Free. We manufacture these assemblies with a full array of sanitary clamp and I-line style fittings, along with molded silicone ends.

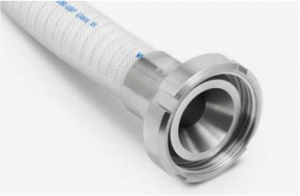

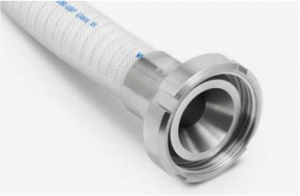

Braid Reinforced Smooth Bore Silicone Hose (available in both Platinum Cured and Peroxide Cured Medical Grade)

4-Ply Mandrel Wrapped Silicone Hose for high pressure

4-Ply Wire Reinforced Mandrel Wrapped Silicone Hose for Vacuum applications

High Purity Tubing Platinum Cured Silicone Tubing

Braid Reinforced Smooth Bore Silicone Hose

Low volatile grade, platinum-cured silicone hose is clean room produced for critical pharmaceutical, biomedical, cosmetic, and food applications. Polyester yarn braiding inside the wall enhances the pressure capabilities. APSH has undergone extensive physical, chemical, and biological testing and meets USP Class VI, FDA CFR 177.2600, ISO 10993, European Pharmacopoeia 3.1.9, 3-A, and NSF-51 standards.

| Part

Number |

I.D.

(in.) |

Wall

(in.) |

O.D.

(in.) |

Working

Pressure PSI at 70°F (21.1°C) |

Bend

Radius (in.) |

Weight

per Foot (lb) |

| APSH-P-0063 | .063 | .105 | .282 | 200 | CF | .031 |

| APSH-P-0125 | .125 | .120 | .375 | 175 | CF | .051 |

| APSH-P-0188 | .188 | .130 | .462 | 170 | CF | .073 |

| APSH-P-0250 | .250 | .125 | .500 | 140 | 1 | .077 |

| APSH-P-0375 | .375 | .125 | .625 | 140 | 1 | .102 |

| APSH-P-0500 | .500 | .187 | .875 | 105 | 3 | .211 |

| APSH-P-0625 | .625 | .170 | .990 | 100 | 3 | .241 |

| APSH-P-0750 | .750 | .175 | 1.125 | 90 | 4 | .287 |

| APSH-P-0875 | .875 | .180 | 1.260 | 65 | 5 | .336 |

| APSH-P-1000 | 1.000 | .190 | 1.405 | 60 | 6 | .401 |

4-Ply Mandrel Wrapped Silicone Hose

Low volatile grade, platinum-cured silicone hose for critical pharmaceutical, biomedical, cosmetic, and food applications comprises the liner of APSM. The liner is then slipped onto a mandrel and wrapped with polyester mesh fabric and additional silicone. It is cured into a homogeneous hose to enhance its pressure capabilities, making it ideal for discharge applications. APSM has undergone extensive physical, chemical, and biological testing.

Meets USP Class VI, FDA CFR 177.2600, ISO 10993, European Pharmacopoeia 3.1.9, 3-A and NSF-51 standards.

APSM is not intended for implantation and is not to be used for continuous steam applications.

| Part

Number |

I.D.

(in.) |

Wall

(in.) |

O.D.

(in.) |

Working

Pressure PSI @ 70F |

Burst

Pressure PSI @ 70F |

Min. Bend

Radius (in.) |

Weight

per Foot (lb) |

| APSM-P-0500 | .500 | .210 | .920 | 150 | 600 | 2.50 | .281 |

| APSM-P-0750 | .750 | .210 | 1.17 | 150 | 600 | 4.50 | .359 |

| APSM-P-1000 | 1.000 | .210 | 1.42 | 150 | 600 | 9.00 | .438 |

| APSM-P-1500 | 1.500 | .210 | 1.92 | 150 | 600 | 12.00 | .685 |

| APSM-P-2000 | 2.000 | .210 | 2.42 | 125 | 500 | CF | .875 |

| APSM-P-2500 | 2.500 | .210 | 2.92 | 125 | 500 | CF | 1.050 |

| APSM-P-3000 | 3.000 | .210 | 3.42 | 100 | 400 | CF | 1.230 |

| APSM-P-4000 | 4.000 | .210 | 4.42 | 100 | 400 | CF | CF |

4-Ply Wire Reinforced Mandrel Wrapped Silicone Hose for Vacuum

Low volatile grade, platinum-cured silicone hose for critical pharmaceutical, biomedical, cosmetic, and food applications comprises the liner of APSW. The liner is then slipped onto a mandrel and wrapped with polyester mesh fabric, 316 stainless steel reinforcing wire, and additional silicone. It is cured into a homogeneous hose to enhance its pressure and vacuum capabilities. APSW has undergone extensive physical, chemical, and biological testing and meets USP Class VI, FDA CFR 177.2600, ISO 1099 and European Pharmacopoeia 3.1.9 standards.

| Part

Number |

I.D.

(in.) |

O.D.

(in.) |

Vacuum

(in./Hg.) |

Working

Pressure PSI @ 70F |

Burst

Pressure* PSI @ 70F |

Bend

Radius (in.) |

Weight

per Foot (lb.) |

| APSW-P-0500 | .500 | .910 | 29.9 | 150 | 600 | 2.00 | .281 |

| APSW-P-0750 | .750 | 1.16 | 29.9 | 150 | 600 | 2.50 | .359 |

| APSW-P-1000 | 1.000 | 1.41 | 29.9 | 150 | 600 | 3.50 | .438 |

| APSW-P-1500 | 1.500 | 1.91 | 29.9 | 150 | 600 | 4.00 | .685 |

| APSW-P-2000 | 2.000 | 2.41 | 29.9 | 150 | 600 | 6.00 | .875 |

| APSW-P-2500 | 2.500 | 2.91 | 29.9 | 125 | 500 | 11.00 | 1.050 |

| APSW-P-3000 | 3.000 | 3.41 | CF | 100 | 400 | 13.00 | 1.230 |

| APSW-P-4000 | 4.000 | 4.41 | CF | 100 | 400 | CF | 1.710 |

High Purity Tubing