AEROSPACE TEMPLATE

Aerospace Assemblies

Flexline produces hose assemblies that meet exacting specifications for the Aerospace industry. Our offerings include PTFE hose, ETFE hose, and corrugated ultra high pressure stainless steel assemblies for both ground support and flight.

Flexline utilizes third party testing facilities, to assure that our assemblies meet aerospace industry and government requirements.

Flexline has in-house passivation and LOX cleaning capabilities. Please contact us for specific requirements.

Available Options Include:

AS604 Heavy Duty High Pressure Teflon Hose

AS614 Ultra High Pressure Teflon Hose

AS620 Convoluted Teflon Hose

AS1055 Heavy Duty High Pressure Teflon Hose

AS1072 Fire Sleeve

AS1227 Convoluted Teflon Hose

AS1424 Metal Hose

AS1339 Light Weight High Pressure Teflon Hose

Mil-H-25579 Medium Pressure Teflon Hose

Mil-H-38360 Ultra High Pressure Teflon Hose

MS33656 37° Fitting Style

NAS1760 Flareless Fitting Style

AS604 (660 Series) R157

QUALIFICATIONS

SAE AS604

TSO C75 Type IIIB-S/P-F

AS1055 Type IIa & IIb, Class A & B, Integral and Slip-on Firesleeve

DESCRIPTION

R157 (660 series) is a heavyweight 3000psi (207 bar) aerospace hose assembly qualified to AS604. The hose consists of an extruded smoothbore PTFE innercore, reinforced with multiple layers of CRES 304 wire braid. The PTFE innercore is conductive and provides excellent chemical resistance through a temperature range of -65ºF to +400ºF (-54ºC to +204ºC) with unlimited shelf life. The 660 Series is especially suited to applications with significant impulsing, and outputs from hydraulic or pneumatic pumps. Standard fittings are CRES, however titanium fittings are also available. Fire protection per AS1055 Class A & B can be either integral, or slip-on AS1072 firesleeve. Chafe sleeves are available in a variety of integral or slip-on materials.

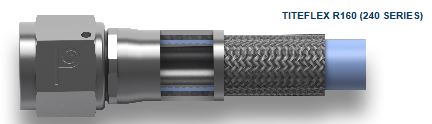

AS1339 (240 Series) R160

QUALIFICATIONS

SAE AS1339

TSO C75 Type IIIB-S/P-F

AS1055 Type IIa & IIb, Class A & B,

Integral and Slip-on Firesleeve

DESCRIPTION

R157 (660 series) is a heavyweight 3000psi (207 bar) aerospace hose assembly qualified to AS604. The hose consists of an extruded smoothbore PTFE innercore, reinforced with multiple layers of CRES 304 wire braid. The PTFE innercore is conductive and provides excellent chemical resistance through a temperature range of -65ºF to +400ºF (-54ºC to +204ºC) with unlimited shelf life. The 660 Series is especially suited to applications with significant impulsing, and outputs from hydraulic or pneumatic pumps. Standard fittings are CRES, however titanium fittings are also available. Fire protection per AS1055 Class A & B can be either integral, or slip-on AS1072 firesleeve. Chafe sleeves are available in a variety of integral or slip-on materials.

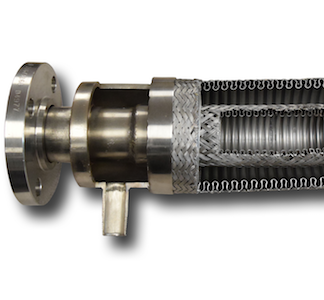

METAL HOSE PAGE

METAL HOSE

FLEXLINE’S STAINLESS STEEL METAL HOSE ASSEMBLIES

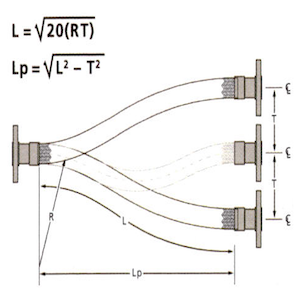

Flexline is the most dependable and one of the largest manufacturers of stainless steel hose assemblies. We manufacture a full range of flexible metal hose and metal hose assemblies in sizes 3/16” ID to 24” ID. Flexline’s engineered system assures our customers of uniform quality. Our welding personnel, procedures, and processes meet exacting specifications and codes.

SPECIALTY ASSEMBLIES/EXPANSION JOINTS

FLEXLINE METAL HOSE INFORMATION

TEFLON HOSE PG- TITLE-TEXT-8 PRODUCTS

FLEXLINE’S TEFLON HOSE

Flexline fabricates a full range of Teflon hose assemblies. Flexline’s broad spectrum of Teflon hose assemblies incorporate a wide range of materials for special applications such as temperature maintenance, chlorine transfer, compressed gas and cryogenic transfer or filling. In order to meet your specific needs, we offer over 40 styles of end connections to fit any application. Our partnership with Saint Gobain – Versilon, Titeflex, Kongsberg, Resistoflex and United Flexible assures our customers of the finest materials and quality.

MEDIUM PRESSURE TEFLON HOSE

HIGH PRESSURE TEFLON HOSE

ULTRA HIGH PRESSURE TEFLON HOSE

HIGH PRESSURE GAS HOSE

CHLORINE TRANSFER HOSE ASSEMBLIES

ELECTRICALLY HEATED HOSE

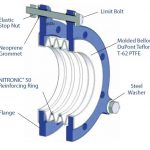

TEFLON EXPANSION JOINTS

SLEEVES AND GUARDS

General Product Template

Flexline offers custom made electrically heated hose assemblies. These assemblies can be made from any of Flexline’s Teflon offerings. Our EHH assemblies feature compact outside diameters, a variety of end connections, FDA materials, and can provide internal temperatures to 250⁰ F.

Applications: Pharmaceuticals, hot glues, filling machines, food applications, hot waxes, cosmetics.

Temperature Range: to 250⁰F

Construction: Externally controlled heaters.

115VAC or 220VAC

J or K thermocouples

RTD available

All external protections offered including: silicone, FEP, stainless steel armor, PVDF chafe guards, etc.

General Spec Template TITLE-PIC_SQ_IMG-SPECS

TITLE HERE

TEXT BLOCK HERE

Applications: High Pressure Gases and Liquids applications that require strength and reliability.

Temperature Range: -65⁰F to 400⁰F continuous service

Standards: Conductive PTFE post sintered antistatic tube

Pre-tensioned Stainless steel 304 braid

| Part # | ID Avg | OD Avg | MAWP PSI | Burst PSI | Min Bend Radius | Weight lb/ft |

| R160-4 | .222″ | .375″ | 5000 | 15000 | 1.5″ | 0.1 |

| R160-6 | .308″ | .475″ | 5000 | 15000 | 2.5″ | 0.16 |

| R160-8 | .403″ | .600″ | 5000 | 15000 | 2.87″ | 0.23 |

| R160-10 | .505″ | .715″ | 5000 | 15000 | 3.25″ | 0.23 |

| R160-12 | .630″ | .970″ | 5000 | 15000 | 3.87″ | 0.66 |

| R160-16 | .867″ | 1.25″ | 5000 | 15000 | 5.0″ | 1.02 |

| R160-20 | 1.118″ | 1.60″ | 5000 | 15000 | 12.0″ | 1.85 |

| R160-24 | 1.383″ | 1.87″ | 4000 | 12000 | 14.0″ | 1.91 |

General Spec Template-TITLE-TEXTBOX-2IMAGES

TITLE HERE

TEXT BLOCK HERE

Applications: High Pressure Gases and Liquids applications that require strength and reliability.

Temperature Range: -65⁰F to 400⁰F continuous service

Standards: Conductive PTFE post sintered antistatic tube

Pre-tensioned Stainless steel 304 braid

General Spec Template-WIDE IMG____TITLE-TEXTBOX-LGIMG-SPECS

TEXT BLOCK HERE

Applications: High Pressure Gases and Liquids applications that require strength and reliability.

Temperature Range: -65⁰F to 400⁰F continuous service

Standards: Conductive PTFE post sintered antistatic tube

Pre-tensioned Stainless steel 304 braid

| Part # | ID Avg | OD Avg | MAWP PSI | Burst PSI | Min Bend Radius | Weight lb/ft |

| R160-4 | .222″ | .375″ | 5000 | 15000 | 1.5″ | 0.1 |

| R160-6 | .308″ | .475″ | 5000 | 15000 | 2.5″ | 0.16 |

| R160-8 | .403″ | .600″ | 5000 | 15000 | 2.87″ | 0.23 |

| R160-10 | .505″ | .715″ | 5000 | 15000 | 3.25″ | 0.23 |

| R160-12 | .630″ | .970″ | 5000 | 15000 | 3.87″ | 0.66 |

| R160-16 | .867″ | 1.25″ | 5000 | 15000 | 5.0″ | 1.02 |

| R160-20 | 1.118″ | 1.60″ | 5000 | 15000 | 12.0″ | 1.85 |

| R160-24 | 1.383″ | 1.87″ | 4000 | 12000 | 14.0″ | 1.91 |

Main Product Landing Page

TEFLON® HOSE

Flexline fabricates a full range of Teflon hose assemblies. Flexline’s broad spectrum of Teflon hose assemblies incorporate a wide range of materials for special applications such as temperature maintenance, chlorine transfer, compressed gas and cryogenic transfer or filling. In order to meet your specific needs, we offer over 40 styles of end connections to fit any application. Our partnership with Saint Gobain – Versilon, Titeflex, Kongsberg, Resistoflex and United Flexible assures our customers of the finest materials and quality.

Main Product Page 3

Flexline is a leading manufacturer of specialty hose assemblies. We are expert in manufacturing Stainless Steel Metal, Teflon, Silicone, Composite and Rubber hose assemblies.

We service OEM, aerospace, distribution and specialty industries. Founded in 1950, we are in our 7th decade of service.

MAIN PRODUCT

Sub Product ONE

Sub Product TWO A

Sub Product THREE

MAIN PRODUCT

Sub Product ONE

Sub Product TWO A

Sub Product THREE

HOME PAGE 3 (MPP3)

MAIN PRODUCT

Sub Product ONE

Sub Product TWO A

Sub Product THREE

MAIN PRODUCT

Sub Product ONE

Sub Product TWO A

Sub Product THREE

MAIN PRODUCT

Sub Product ONE

Sub Product TWO A

Sub Product THREE

MAIN PRODUCT

Sub Product ONE

Sub Product TWO A

Sub Product THREE

Flexline’s larger new facility is specifically designed for the manufacture of assemblies. This will enable us to ship orders even faster. It has also enabled us to offer new processes such as passivation additional testing options.

Product Detail Page

Medium Pressure Teflon Hose

Applications: Compressed Gases, fuel and lubricant handling, steam, hydraulic fluid,

Temperature Range: -65⁰F to 400⁰F continuous service

-100⁰F to 500⁰F intermittent service

Standards: Meets or exceeds SAE 100R14

PTFE meets FDA 21 CFR 177.1550

DuPont type 62 fine grade resin or equal

Stainless steel 304 braid – standard

Vacuum Service: Size -4 to -10 are rated for full vacuum -12 and above are rated to ~ 12” Hg

.040 WALL HOSE

| Part # | Nom Size | ID Avg | OD Avg | MAWP PSI | Burst PSI | Min Bend Radius | Weight lb/ft |

| R105-4/R144-4 | 1/4″ | .187″ | .323″ | 3000 | 12000 | 2″ | 0.08 |

| R105-5/R144-5 | 5/16″ | .250″ | .386″ | 3000 | 12000 | 2.5″ | 0.09 |

| R105-6/R144-6 | 3/8″ | .312″ | .451″ | 2500 | 10000 | 4″ | 0.11 |

| R105-8/R144-8 | 1/2″ | .406″ | .566″ | 2000 | 8000 | 4.6″ | 0.14 |

| R105-10/R144-10 | 5/8″ | .500″ | .665″ | 1500 | 6000 | 5.5″ | 0.19 |

| R105-12/R144-12 | 3/4″ | .625″ | .795″ | 1200 | 4800 | 6.5″ | 0.23 |

| R105-16/R144-16 | 1″ | .875″ | 1.06″ | 800 | 3200 | 9″ | 0.3 |

.030 WALL HOSE

| Part # | Nom Size | ID Avg | OD Avg | MAWP PSI | Burst PSI | Min Bend Radius | Weight lb/ft |

| R115/R122-3 | 3/16″ | .125″ | .234″ | 3000 | 12000 | 2″ | 0.048 |

| R115/R122-4 | 1/4″ | .187″ | .312″ | 3000 | 12000 | 2″ | 0.058 |

| R115/R122-5 | 5/16″ | .250″ | .375″ | 3000 | 12000 | 3″ | 0.078 |

| R115/R122-6 | 3/8″ | .312″ | .445″ | 2500 | 10000 | 4″ | 0.098 |

| R115/R122-6T | 3/8″ | .375″ | .503″ | 2250 | 9000 | 4.5″ | 0.105 |

| R115/R122-8 | 1/2″ | .406″ | .549″ | 2000 | 8000 | 5.2″ | 0.126 |

| R115/R122-10 | 5/8″ | .500″ | .648″ | 1500 | 6000 | 6.5″ | 0.154 |

| R115/R122-12 | 3/4″ | .625″ | .778″ | 1200 | 4800 | 7.7″ | 0.19 |

| R115/R122-12T | 3/4″ | .755″ | .886″ | 1100 | 4400 | 8.2″ | 0.211 |

| R115/R122-16 | 1″ | .875″ | 1.030″ | 1000 | 4000 | 9″ | 0.58 |

| R115/R122-16T | 1″ | 1.00″ | 1.135″ | 900 | 3600 | 10″ | 0.322 |

| R115-R122-16Z | 1″ | .875″ | 1.065″ | 1250 | 5000 | 9″ | 0.459 |

| R115/R122-20 | 11/4″ | 1.125″ | 1.315″ | 800 | 3200 | 16″ | 0.369 |

Product Spec Template

CORRUGATED STAINLESS STEEL HOSE

S Series: ISO 10380 Qualified

Construction: Closed Pitched 321 and 316L stainless steel hose with 304 Braid.

Withstands full vacuum and pressure as listed. Very flexible and durable.

S0-321 Hose No Braid

S1-321 Hose and Single Braid

S2-321 Hose and Double Braid

60 -316L Hose No Braid

61 -316L Hose and Single Braid

62 – 316L Hose and Braid

| Nominal Inside Diameter | Hose Type |

Outside Diameter | Bend Radius Constant Flexing | Bend Radius Static Bend |

Minimum Live Length For Vibration |

Maximum Working Pressure | Burst Pressure @70°F |

| 1/4″ | S0-4 | 0.40 | 145 | ||||

| S1-4 | 0.45 | 4 | 1 | 3.00 | 2420 | 9680 | |

| S2-4 | 0.50 | 3190 | 12760 | ||||

| 3/8” | S0-6 | 0.59 | 80 | ||||

| S1-6 | 0.64 | 6 | 2 | 3.50 | 1450 | 5800 | |

| S2-6 | 0.69 | 2580 | 10320 | ||||

| 1/2” | S0-8 | 0.77 | 80 | ||||

| S1-8 | 0.83 | 6 | 2 | 4.25 | 1075 | 4300 | |

| S2-8 | 0.88 | 1500 | 1500 | ||||

| 3/4” | S0-12 | 1.02 | 60 | ||||

| S1-12 | 1.08 | 8 | 4 | 4.50 | 950 | 3800 | |

| S2-12 | 1.14 | 1250 | 5000 | ||||

| 1″ | S0-16 | 1.33 | 60 | ||||

| S1-16 | 1.41 | 8 | 4 | 5.50 | 725 | 2900 | |

| S2-16 | 1.49 | 1110 | 4470 | ||||

| 1 1/4” | S0-20 | 1.62 | 50 | ||||

| S1-20 | 1.70 | 10 | 5 | 6.00 | 563 | 2252 | |

| S2-20 | 1.78 | 825 | 3300 | ||||

| 1 1/2” | S0-24 | 1.88 | 35 | ||||

| S1-24 | 1.95 | 10 | 5 | 6.25 | 500 | 2000 | |

| S2-24 | 2.02 | 800 | 3200 | ||||

| 2″ | S0-32 | 2.44 | 15 | ||||

| S1-32 | 2.53 | 13 | 7 | 7.50 | 478 | 1912 | |

| S2-32 | 2.61 | 638 | 2552 | ||||

| 2 1/2” | S0-250 | 3.23 | 12 | ||||

| S1-250 | 3.33 | 20 | 8 | 11 | 410 | 1640 | |

| S2-250 | 3.43 | 656 | 2624 | ||||

| 3” | S0-300 | 3.78 | 10 | ||||

| S1-300 | 3.88 | 22 | 9 | 12 | 335 | 1340 | |

| S2-300 | 3.98 | 536 | 2145 | ||||

| 4” | S0-400 | 4.85 | 8 | ||||

| S1-400 | 4.98 | 27 | 13 | 14 | 240 | 960 | |

| S2-400 | 5.08 | 384 | 1536 | ||||

| 5″ | S0-500 | 5.90 | 6 | ||||

| S1-500 | 6.03 | 31 | 18 | 15 | 191 | 764 | |

| S2-500 | 6.15 | 306 | 1222 | ||||

| 6” | S0-600 | 6.87 | 5 | ||||

| S1-600 | 7.10 | 36 | 19 | 16 | 165 | 660 | |

| S2-600 | 7.33 | 264 | 1056 | ||||

| 8” | S0-800 | 9.09 | 6 | ||||

| S1-800*

|

9.19 | 40 | 20 | 17 | 234 | 934 | |

| S2-800* | 9.28 | 40 | 20 | 17 | 374 | 1495 | |

| 10” | S0-1000 | 11.18 | 6 | ||||

| S1-1000* | 11.32 | 50 | 25 | 18 | 234 | 934 | |

| S2-1000* | 11.45 | 374 | 1495 | ||||

| 12″ | S0-1200 | 13.23 | 3 | ||||

| S1-1200* | 13.37 | 60 | 30 | 20 | 160 | 643 | |

| S2-1200* | 13.50 | 257 | 1029 | ||||

| 14” | S0-1400 | 14.70 | 14.7 | ||||

| S1-1400* | 14.84 | 70 | 35 | 22 | 119 | 476 | |

| S2-1400* | 14.98 | 190 | 762 |

H Series: Heavy Wall Hose

Construction: 321 or 316 stainless steel heavy wall hose with 304 braid. High pressure containment capabilities.

H1- 321 Stainless Hose 304 Single Braid

H2- 321 Stainless Hose 304 Double Braid

6H1-316 Stainless Hose Single 304 Braid

6H2-316 Stainless Hose 304 Double Braid

| Nominal Inside Diameter | Hose Type |

Outside Diameter | Bend Radius Constant Flexing | Bend Radius Static Bend |

Maximum Working Pressure | Burst Pressure @70°F |

| 1/4” | H1-4 | 0.57 | 5 | 1.00 | 2562 | 10250 |

| H2-4 | 0.64 | 4099 | 16400 | |||

| 3/8″ | H1-6 | 0.67 | 6.0 | 3.0 | 1501 | 6004 |

| H2-6 | 0.73 | 8.0 | 4.0 | 2401 | 9604 | |

| 1/2″ | H1-8 | 0.83 | 7.5 | 4.5 | 2194 | 8777 |

| H2-8 | 0.89 | 10.0 | 6.0 | 3510 | 14040 | |

| 3/4” | H1-12 | 1.16 | 9.0 | 6.0 | 1311 | 5244 |

| H2-12 | 1.26 | 12.0 | 8.0 | 3510 | 14040 | |

| 1” | H1-16 | 1.43 | 10.5 | 6.8 | 1069 | 4276 |

| H2-16 | 1.54 | 14.0 | 9.0 | 1710 | 6840 | |

| 1 1/4″ | H1-20 | 1.87 | 13.5 | 4.5 | 1111 | 4444 |

| H2-20 | 1.98 | 18.0 | 6.0 | 1776 | 7040 | |

| 1 1/2″ | H1-24 | 2.19 | 16.5 | 5.3 | 868 | 1887 |

| H2-24 | 2.25 | 22.0 | 7.0 | 1388 | 5552 | |

| 2” | H1-32 | 2.65 | 18.0 | 6.8 | 810 | 3240 |

| H2-32 | 2.78 | 24.0 | 9.0 | 1296 | 5184 | |

| 2 1/2″ | H1-250 | 3.42 | 19.5 | 7.5 | 578 | 2312 |

| H2-250 | 3.53 | 26.0 | 10.0 | 925 | 3700 | |

| 3″ | H1-300 | 3.98 | 24.0 | 11.3 | 540 | 2160 |

| H2-300 | 4.09 | 32.0 | 15.0 | 864 | 3456 | |

| 4″ | H1-400 | 4.92 | 30.0 | 15.0 | 333 | 1332 |

| H2-400 | 5.03 | 40.0 | 20.0 | 533 | 2132 | |

| 6″ | H1-600 | 7.12 | 45.0 | 22.5 | 266 | 1062 |

| H2-600 | 7.26 | 60.0 | 30.0 | 425 | 1700 | |

| 8″ | H1-800* | 9.34 | 60.0 | 30.0 | 200 | 800 |

| H2-800* | 9.56 | 80.0 | 40.0 | 300 | 1200 |

TEXT BOX 4 BUTTONS

BLUE BUTTONS FOR PRODUCTS

HOME TOP TEXT BOX

Flexline is a leading manufacturer of specialty hose assemblies. We are expert in manufacturing Stainless Steel Metal, Teflon, Silicone, Composite and Rubber hose assemblies.

We service OEM, aerospace, distribution and specialty industries. Founded in 1950, we are in our 7th decade of service.

8 pics w/ title

SANITARY / HYGENIC HIGH PURITY HOSES AND FITTINGS

RUBBER COVERED TEFLON HOSE

STAINLESS STEEL BRAIDED TEFLON HOSE

TEFLON HOSE FITTINGS

SILICONE HOSE

FDA HOSE

SANITARY FITTINGS AND VALVES

SILICONE TUBING

COMPLIMENTARY PRODUCTS

SANITARY PRODUCT PAGE

.

RUBBER COVERED TEFLON HOSE

Ultra-smooth inside and outside surfaces with smoothness ratings to 20Ra, flexible with excellent bend radii, can be sterilized and autoclaved.

Approvals: FDA per 21CFR177.1550

Pharmacopeia Class VI

3-A Sanitary Standard 62-01

Applications: Load Cells, CIP applications, transfer lines, process lines.

Temperature Range: -40⁰F to 350⁰F continuous service

Construction: Inner tube: Chemflour FEP

Reinforcement: Multiple polyester plycord and EPDM rubber with high tensile double helix steel wire

Cover: Ultra Smooth EPDM, Light gray with white lay line.

Fittings: All stainless steel and flare thru offerings including: sanitary clamp, bevel and I-Line style, flanges, cam locks, male pipe thread, female JIC swivels.

SANITARY MAIN

.

SANITARY / HYGENIC HIGH PURITY HOSES AND FITTINGS

Flexline fabricates a full range of High Purity Fittings and Valves and Sanitary Teflon hose assemblies. We stock sanitary fittings, sanitary valves, sanitary gaskets, clamp style sanitary hose fittings as well as I-line fittings. We feature Saint Gobain, Resistoflex, Newman, Dixon Sanitary, Topline, and many others. Our hose assemblies and fittings protect the integrity of your operations and your sanitary products, increase productivity, and ensure high output. Flexline’s Sanitary hoses are used in many critical applications including – biopharmaceutical production, food and beverage manufacturing, dairy processing, cryogenics, and cosmetic manufacturing.

HYDRAULIC PRODUCT PAGE

.

HYDRAULIC HOSE COUPLINGS

Flexline is an authorized Parker, Kurt and Parflex fabricator. We assemble a complete range of rubber and thermoplastic hydraulic hoses for OEM, Construction, Transportation, Manufacturing, and Military applications. We carry both American and Metric fittings as well as SAE and DIN hoses.

Flexline also offer hydraulic adapters, hydraulic flanges, hydraulic oil, quick disconnects, ultra-high pressure assemblies, and both crimp and reusable couplings.

Medium Pressure Hydraulic Hose:

SAE 100R1

SAE100R2

SAE10016-S

SAE100R5

Tough Cover

Thermoplastic

Parflex

High Pressure

SAE100R12

DIN EN 856

Specialty

Pushlok Hose

SAE100R4

Suction Hose

Refrigerant LPG

Our coupling offerings include:

Crimp Couplings

Reusable Couplings

Code 61&62 Hydraulic Flanges

JIC 37⁰ configurations

Pipe Threads

Kamatsu Style

O-ring face seal

Din Metric Fittings

Komatsu hydraulic flanges

O-ring straight thread

Compression

BSP/JIS

Refrigeration Fittings

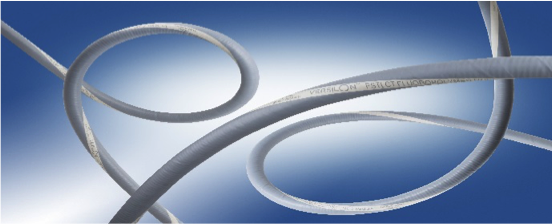

TEFLON HOSE HIGH PRESSURE

.

HIGH PRESSURE TEFLON HOSE

Applications: High Pressure Gases and Liquids applications that require strength and reliability.

Temperature Range: -65⁰F to 400⁰F continuous service

Standards: Conductive PTFE post sintered antistatic tube – Pre-tensioned Stainless steel 304 braid

| Part # | ID Avg | OD Avg | MAWP PSI | Burst PSI | Min Bend Radius | Weight lb/ft |

| R160-4 | .222″ | .375″ | 5000 | 15000 | 1.5″ | 0.1 |

| R160-6 | .308″ | .475″ | 5000 | 15000 | 2.5″ | 0.16 |

| R160-8 | .403″ | .600″ | 5000 | 15000 | 2.87″ | 0.23 |

| R160-10 | .505″ | .715″ | 5000 | 15000 | 3.25″ | 0.23 |

| R160-12 | .630″ | .970″ | 5000 | 15000 | 3.87″ | 0.66 |

| R160-16 | .867″ | 1.25″ | 5000 | 15000 | 5.0″ | 1.02 |

| R160-20 | 1.118″ | 1.60″ | 5000 | 15000 | 12.0″ | 1.85 |

| R160-24 | 1.383″ | 1.87″ | 4000 | 12000 | 14.0″ | 1.91 |